Not a Number, but a Complete Lubrication Strategy

In engine lubrication, viscosity is often simplified into a single grade on the label.

In reality, viscosity defines how oil behaves under different temperatures, loads, and operating conditions, and whether a stable oil film can be maintained where protection matters most.

From a manufacturing perspective, the right viscosity is never universal.

It must be designed for the engine, the climate, and the way the vehicle is actually used.

Engine oil viscosity is not a marketing figure.

It is a lubrication strategy built around the engine, the climate, and real operating conditions.When viscosity is engineered for real-world use, engine oil can provide reliable protection whether operating at –40 °C in cold climates or under sustained high temperatures in demanding environments.

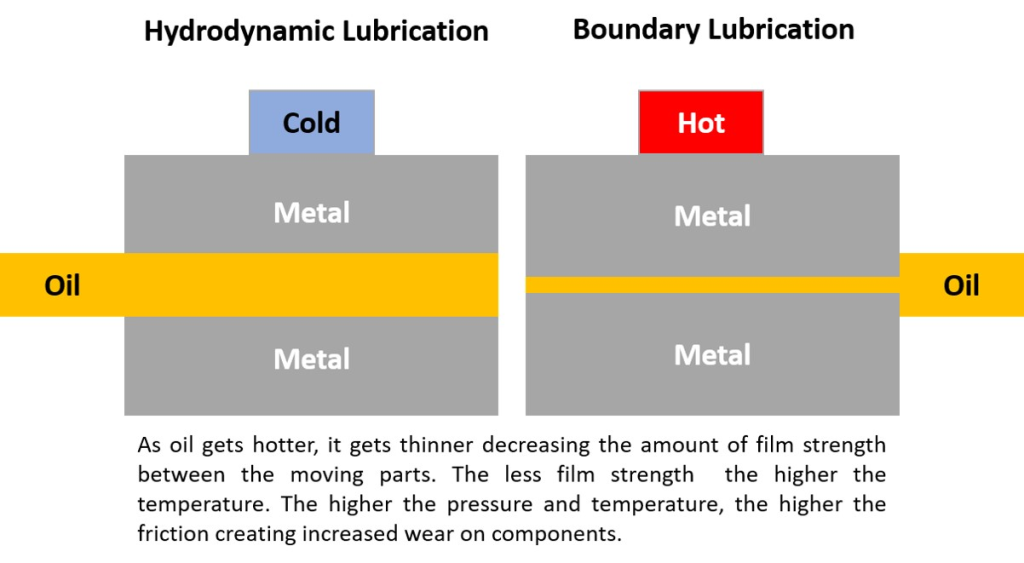

The role of viscosity: controlling the oil film, not thickness alone

Lubrication inside an engine does not depend on how “thick” the oil feels.

It depends on whether a continuous oil film can separate metal surfaces under motion.

- If viscosity is too low, the oil film may collapse under load

- If viscosity is too high, flow is restricted, especially during cold starts

The purpose of viscosity is to balance flowability and film strength across the full operating range of the engine.

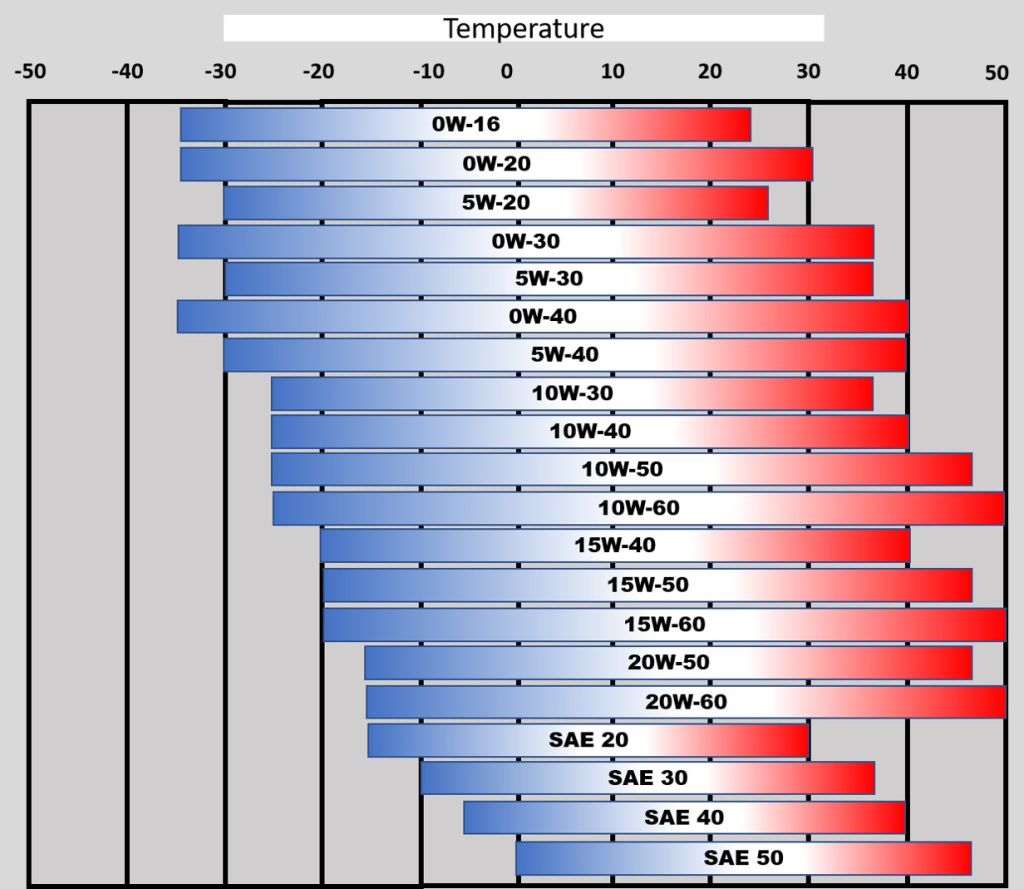

Cold climates: flowability determines start-up protection

In cold regions such as Russia, engines face extreme low-temperature conditions.

At temperatures as low as –40 °C, improper viscosity control can lead to:

- Difficult or delayed cold starts

- Slow oil circulation to critical components

- Increased wear during the initial seconds after start-up

For these environments, engine oil must maintain excellent low-temperature pumpability while still forming a stable oil film once operating temperature is reached.

This is why, in cold-climate markets,

low-temperature viscosity behavior and viscosity index stability are often more critical than high-temperature figures alone.

Hot climates: oil film stability determines long-term durability

In contrast, regions such as the Middle East expose engines to high ambient temperatures and prolonged high-load operation.

Under these conditions, oil with insufficient high-temperature viscosity may thin excessively, reducing film strength.

For reliable performance in hot climates, engine oil must provide:

- Adequate viscosity retention at elevated temperatures

- Strong resistance to mechanical shear

- Stable viscosity behavior during extended operation

In these markets, high-temperature high-shear (HTHS) performance often matters more than the nominal viscosity grade.

Different engines require different viscosity strategies

Engine design and usage patterns naturally lead to different viscosity requirements:

- Turbocharged, downsized engines rely on fast oil circulation and high-temperature stability

- Naturally aspirated engines emphasize cleanliness and long-term lubrication stability

- High-mileage or heavily loaded engines benefit from stronger oil film load-bearing capacity

For this reason, viscosity selection should be matched to engine architecture, operating stress, and service interval, not applied uniformly across all vehicles.

Viscosity stability comes from base oil and additive balance

Engine oil viscosity is not static during service.

Heat, oxidation, and mechanical shear continuously influence its behavior.

This is why we use new, virgin base oils and region-specific additive systems designed to:

- Maintain viscosity index stability

- Resist high-temperature oxidation and shear thinning

- Preserve low-temperature flow characteristics

Viscosity performance is not achieved by simply “thickening” the oil,

but through a balanced formulation of base oil quality and additive chemistry.

Climate and vehicle determine viscosity, not market labels

In real-world applications, we follow one fundamental principle:

environment and engine come before viscosity grade selection.

- Cold regions prioritize low-temperature flow and start-up protection

- Hot regions prioritize oil film strength and thermal stability

- Different vehicles require different viscosity ranges based on design and load

This approach allows engine oils to perform consistently across extreme climates while remaining predictable throughout their service life.