From Oil Filters to Cabin Air Filters

Whether it is an oil filter or a cabin air filter, long-term reliability is not determined by laboratory figures alone.

It is determined by how well the product is designed for real operating environments.

From a manufacturing perspective serving multiple global markets, one principle remains constant: filters must be engineered for climate and usage conditions—not only for specifications.

Most filter problems come from climate mismatch, not filtration efficiency

In real-world use, filter failures rarely occur because filtration efficiency is too low.

They occur because environmental factors were underestimated during design.

Typical challenges include:

- High dust and particle loading

- Material degradation under extreme heat

- Brittleness and shrinkage in extreme cold

- Structural fatigue over long service intervals

If these factors are not addressed at the design stage, issues tend to appear later in the service cycle—often unexpectedly.

Filters are not products that succeed through parameter stacking alone.

Their reliability comes from a balanced understanding of climate, materials, and structural behavior.When filters are engineered for real environmental conditions—

whether sand, heat, or extreme cold—

they cease to be a weak point and become a stable part of the system.

Middle East markets: dust load management matters more than filtration limits

In Middle Eastern environments, frequent sandstorms and high airborne particle concentrations place significant stress on both oil filters and cabin air filters.

Under these conditions, the main risk is not insufficient filtration,

but premature restriction caused by uneven particle accumulation.

For products supplied to these regions, design priorities typically include:

- Uniform fiber distribution to avoid localized clogging

- Sufficient effective filtration area to disperse dust load

- Stable flow characteristics even under heavy particle exposure

For cabin air filters in particular,

maintaining continuous airflow under dusty conditions is as critical as filtration efficiency itself.

Russia and cold-climate regions: material behavior defines reliability

In regions where temperatures regularly fall far below freezing,

filters face challenges that are fundamentally different from high-temperature environments.

In extreme cold, improper material selection can lead to:

- Brittle filter media and fiber fracture

- Seal shrinkage causing bypass or leakage

- Structural fatigue under repeated thermal cycling

For cold-climate applications, design focus shifts toward:

- Media flexibility retention at low temperatures

- Dimensional stability of sealing materials

- Structural durability under repeated cold-start conditions

These factors largely determine whether a filter can perform reliably throughout its intended service life.

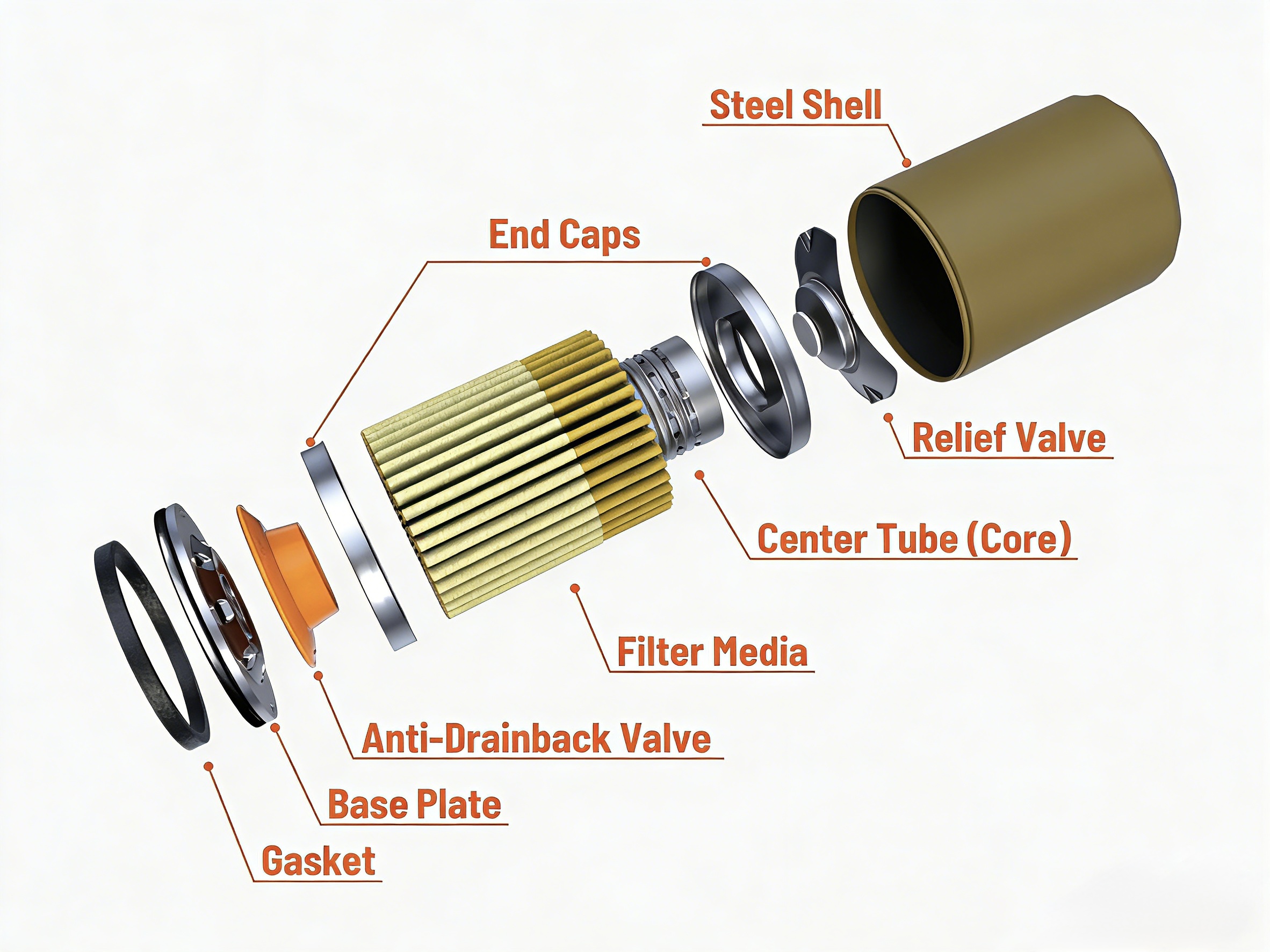

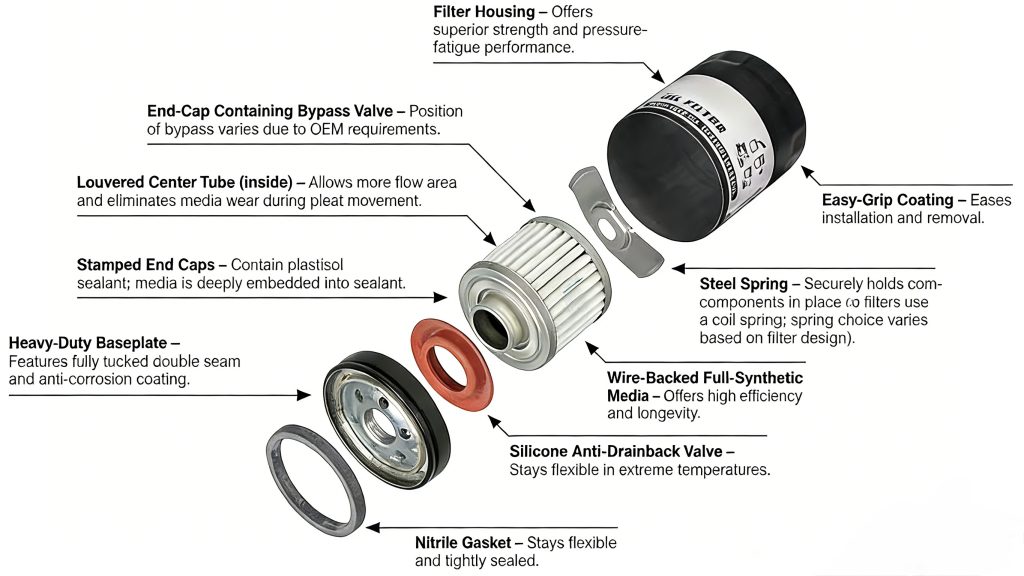

Oil filters and cabin air filters differ in function, but share the same principles

Although oil filters and cabin air filters operate in different systems,

their reliability is governed by common engineering principles:

- Filtration must remain stable, not aggressive

- Structural integrity must be maintained over the entire service interval

- Performance degradation should be predictable and controlled

Whether exposed to high temperature and pressure in lubrication systems,

or dust, humidity, and temperature extremes in air handling systems,

filters must perform their task without disrupting system operation.

Why long-term performance remains stable across extreme environments

Through years of supplying filters to markets such as the Middle East and Russia,

our approach has remained consistent:

- Design based on real operating conditions

- Conservative material selection with sufficient safety margins

- Evaluation focused on mid- and late-cycle performance, not only initial results

As a result, greater emphasis is placed on how filters perform

months into service, not just at installation.

Consult the model that best suits your needs — we will provide you with the most reliable technical support and assistance.

Stay tuned for our upcoming blog posts, where we’ll deep dive into specific aspects of the future of electronics, showcasing the latest developments, trends, and possibilities.

where we’ll deep dive into specific aspects of the future of electronics, showcasing the latest developments, trends, and possibilities.